Ts'ebetso ea ho khabisoa ea lishiti tsa 'mabole tsa PVC tse kentsoeng le liphanele tse amanang haholo-holo li itšetlehile ka theknoloji ea extrusion, ho netefatsa tlhahiso e sebetsang le e tsitsitseng.(Setšoantšo1)(Setšoantšo2)

Taba ea pele, ts'ebetso ea extrusion e theha letlapa la PVC la motheo. Joale, ka mokhoa o chesang oa khatiso oa lamination (ho hatella le ho laminating), lipampiri tse fapa-fapaneng tse mebala-bala tsa filimi li khomaretsoe ka thata holim'a lakane, e fana ka tlhaloso e ruileng ea mebala, e behang motheo oa ho finyella liphello tse sa tšoaneng tsa pono tse kang ho etsisa lejoe kapa phekolo ea 'mabole.(Setšoantšo3)(Setšoantšo4)

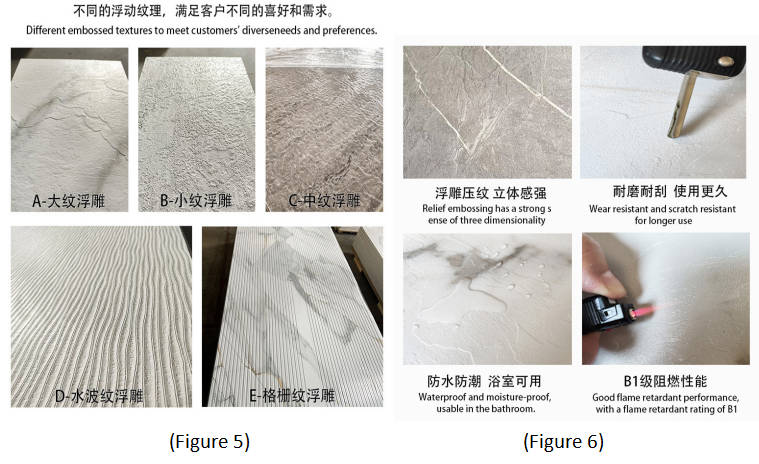

Mohato oa bohlokoa oa ho theha sebopeho se khabisitsoeng ke ho hatella ka li-rollers tse khabisitsoeng. Lirolara tsena li tla ka mekhoa e fapaneng, ho kenyelletsa le lipaterone tse kholo, lipaterone tse nyane, maqhubu a metsi le lipaterone tsa grille. Ha letlapa la PVC, ka mor'a ho lamination, le feta ka li-rollers tse khabisitsoeng tlas'a mocheso o laoloang le khatello, litlolo tse khethehileng tsa li-rollers li fetisetsoa holim'a metsi hantle. Ts'ebetso ena e fella ka litlamorao tse ikhethang, ho etsa hore liphanele li be le pheletso ea mahlakore a mararo le a tactile.(Setšoantšo5)(Setšoantšo6)

Motsoako ona oa extrusion, mocheso o hatellang lamination, le embossing roller tobetsa e lumella tlhahiso ea liphanele tsa PVC tse nang le mebala e fapaneng le lipaterone tse hatisitsoeng, joalo ka liphanele tsa mothapo oa lejoe la PVC. E kopana ka katleho le likhetho tse fapaneng le litlhoko tse sebetsang tsa bareki ba fapaneng mokhabisong oa kahare le masimong a mang.

Nako ea poso: Jul-31-2025